Call 717-238-1444 For A Quote

Opto-Electronic (Optoflex) Fiber Optic Cable Protection From AerosUSA

Laser and Fiber Optic systems exist in numerous environments under a variety of physical demands. Tensile stresses, mechanical bending of fibers, temperature changes and other environmental factors are some of the elements that can put your system at risk without the proper cable protection. To keep your equipment, fiber optic / laser/ medical, in good condition for years to come, you need a safe and compliant protected system.

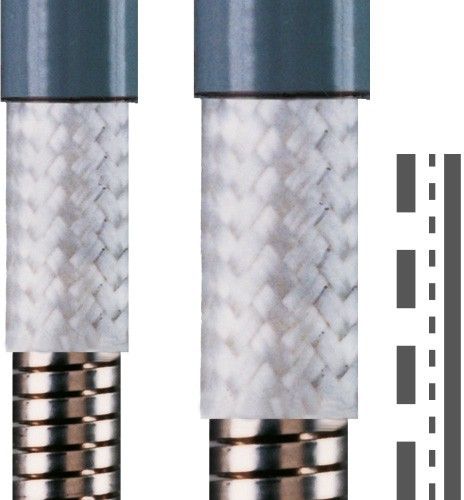

Our Optoflex products are the ideal solution to safeguard and protect fiber optic wires and cables against the elements. Our specialized fiber conduits provide ultimate cable strain relief and can protect your wires and cables against heat, cold, moisture, dirt, dust, pressure stress, UV and other potentially harmful environmental influences. We offer a wide range of protective conduits, in a variety of materials, to meet the needs of your application.

APPLICATIONS OF OUR FIBER OPTIC PROTECTION TUBING

Our conduits for fiber optic cables see use in opto-electronic instruments for the medical, transportation and industrial field, as well as in commercial and residential settings.

Some of the applications our fiber optic protection tubes currently serve include:

- Laser cutting systems: Cutting and engraving machines use laser optic transport fibers, many of which are on moving heads and can utilize our flexible conduits.

- Fiber optic lighting: Light sources such as light-emitting diodes need wiring protection that withstands everyday environmental factors. Light fixtures outdoors, or in environments like bathrooms, are susceptible to failure without the right wire protection.

- Thermocouples: Industrial facilities and laboratories use thermocouple instruments for measuring high temperatures. Exposed thermocouple wires, while they provide fast response times to temperature changes, will degrade quicker. Our high-temperature-resistant conduits provide sheathing from the surrounding atmosphere.

- Medical equipment: Medical devices used in the body, such as endoscopes and other life-saving equipment, need wire and cable protection, particularly from blood and bodily fluids. Fiber optic conduits are also used to connect cables for powered wheelchairs and mobile MRI equipment.

- Sensors: Opto-electronic sensors are found in various devices that incorporate robotics and automation. In some circumstances, flexible fiber optic tubing is important for cabling that bends with a connected, moving component, or cabling that is moisture-resistant in water-management systems like washing stations.

- Telecommunications: The telecommunications industry is increasing the utilization of fiber optic cabling for modern network infrastructures. Many of these data lines are underground and installed through plowing, trenching or boring cables. Fiber optic cables need abrasion, pressure and moisture resistance for the prolonged periods of time that the network connects telecommunications providers to customers.

Understanding Standard IP Code

Ingress Protection (or IP) ratings are a universal system for understanding the degree of protection that an electronic enclosure provides against various stressors. IP ratings denote reliability against physical or chemical hazards, both accidental and anticipated. These ratings include one digit (from 0-6) about the resistance against foreign bodies and particulates, and a second digit (from 0-9) against moisture, high-pressure washes and immersion.

Always note the IP standard that applies to your industry guidelines or product specifications so you can select the right fiber optic conduit for your opto-electronic system.